Cooling towers are a special kind of heat exchanger devices where air and hot water are brought into direct contact with each other in order for the evaporative cooling to take place and the temperature of the water to drop due to it. During evaporative cooling process the air has to be unsaturated so that it can store the evaporated water vapors and for the water to change its phase from liquid to gas, latent energy is required which the water absorbs from the surrounding.

|

| Cooling Tower Working and Types |

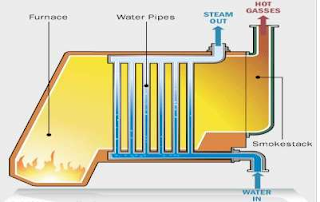

Working of a cooling tower

The working principle of a cooling tower is evaporative cooling.

The hot water is input in the equipment from the top of the cooling tower. The hot water is flows through a pipe and is made to pass through spray nozzles. The water flows in the tower as droplets. The advantage of doing this is that the surface area of contact of air water increases. The water falls down due to the influence of gravity.

The air is input in the equipment through the bottom of the cooling tower.

The water falls on the fill material. The fill materials are the zone where the intimate contact of air and hot water occurs. The fill materials are also sometimes called packings or baffles. The purpose of the fill material is to increase the effective surface area which is responsible for heat transfer.

After the hot water and air come in contact, evaporative cooling takes place which results in decrease in temperature of the water and increase in temperature of the air.

The cooled water is collected from the bottom of the cooling tower and the warm air rises and moves out from the top of the cooling tower.

Types of cooling towers

Air Draft cooling towers are classified as Atmospheric towers, Natural draft towers and Mechanical draft towers. The Mechanical draft towers are further classified into Forced draft type and Induced draft type.

Atmospheric Cooling Towers

This is the simplest type of cooling tower. It consists of a rectangular chamber which has louvered walls on the opposite end. The louvers are devices which act as barrier for splash out and sunlight, also the louvers give a direction to the flowing wind. The atmospheric air enters the cooling tower depending on the speed of the wind guided by the louvers. The tower is filled with fill material on which contact of air and water takes place. They are cheap but inefficient because the performance is largely driven by wind velocity and direction.

Natural Draft Cooling Towers

A natural draft tower is also called hyperbolic tower because it is a large concrete structure of hyperbolic shape. The tower is called so because the movement of air happens naturally inside the tower. The tower consists of a spray mechanism beneath which alternative layers of battens are stacked along with the packing material.

The air enters from the bottom and the water gets splashed when it touches battens and forms the shape of droplets. These droplets result in a good heat transfer area. The rise in temperature of the air and humidity reduces its density due to which it becomes relatively more buoyant and rises naturally. Drift eliminators are placed in the tower to catch the liquid droplets which may be entrained with the air.

Forced Draft Cooling Towers

Forced draft towers are a type of mechanical draft towers because they use fans to move air inside the cooling tower. Forced draft towers use fans at the bottom of the tower in order to push the air inside the cooling tower. The forced mechanism makes it relatively more efficient than a natural draft tower. If the fans are big enough then it may cause the motion of the air to become non-uniform while it passes through the fill material. The biggest disadvantage of forced draft tower is that it may pick up the exit air from outside and push it back inside the cooling tower. This re-circulation reduces the efficiency of the tower because the saturation level of inlet air increases.

Induced Draft Cooling Towers

Induced draft towers are designed to eliminate the re-circulation effect which happens in forced draft towers. The fans in induced draft towers are placed at the top of the cooling tower. The space for air inlet is made at the bottom of the tower. When the fan operates, suction is created at the bottom of the tower due to which the flow of air is induced.

In the counter flow mechanism of the process, the power required to move air will be high because the air entry to the packing will face the maximum resistance due to the liquid exiting the packing. Induced draft towers can be operated in concurrent flow, counter current flow and cross flow.